Frequently Asked Questions

Frequently asked questions, we integrate them into self-service Q&A. If you have other questions, you can get in touch with us Or send us an email to: info@southholding.cn

-

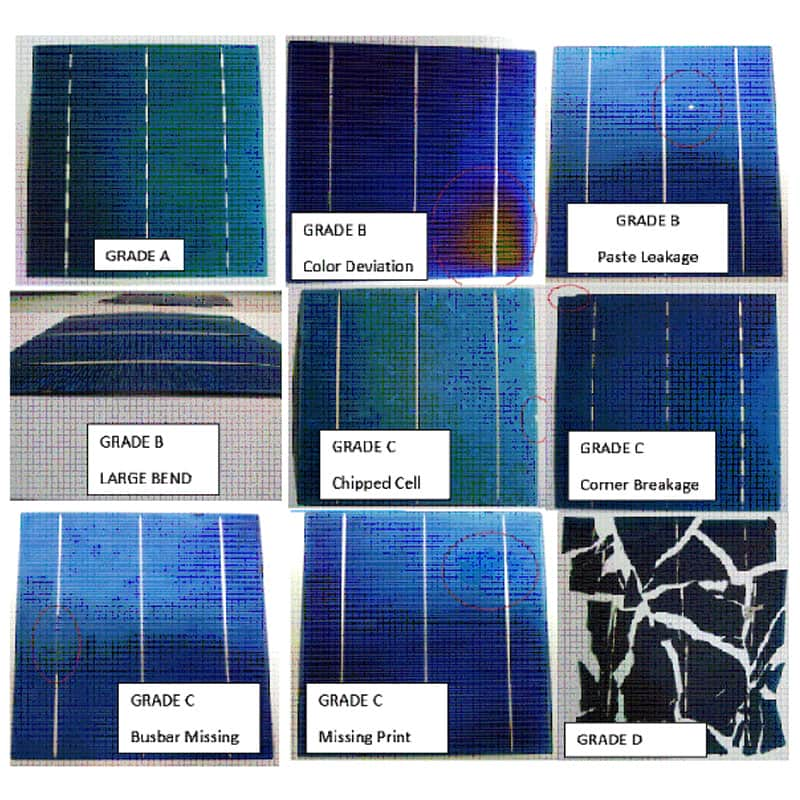

Do you know there are A B C grade for solar cell?+

Do you know there are A B C grade for solar cell?+The grades of solar cell modules are generally divided into A grade, B grade, and C grade, and A grade modules can be divided into A+ and A- grades. Different grades of solar cell modules have a certain cost gap. We will briefly introduce the three grades of A, B and C:

-

grade modules: A-grade is the highest quality grade of cells, and the modules can be used perfectly.

-

level modules: B-level cells are slightly lower than A-level cells, and the modules can be downgraded.

- level modules: C-level cells are those with serious bad appearance and missing corners. These cells can be cut into small modules and supplied to customers with special needs.

For manufacturers, the following three points can be used to detect whether the solar cells meet the usage standards:

Before the case is encapsulated

Visual inspection of battery samples:

The color of the upper surface of the battery should be uniform, no mechanical damage, and no oxidation spots on the solder joints. The upper electrode of the battery and the bottom electrode of the battery should not fall off. The anti-reflection coating should not peel or discolor. Use vernier calipers and micrometers to measure the dimensions and thickness of battery samples, which should conform to product production standards.

After the shell is encapsulated

Physical size check:

Check the physical characteristics and size requirements of the standard battery, such as the distance between the upper surface of the standard battery and the encapsulation glass of the casing, and the size of the encapsulation casing, which conform to the actual product standards.Appearance defect inspection:

After the standard battery is packaged, the appearance defect inspection is carried out, focusing on checking whether the material has internal reflection, and the defects that may be caused during the packaging process, such as air bubbles, delamination, unclear marking, etc. In general, bubbles and delamination defects are the most critical.

For consumers, the quality of solar cells can be judged from the following four points:

Look at the surface of the module: Check whether the surface of the module is smooth and meticulous. Low-grade products are relatively rough, and the residual silica gel on the surface will reduce the power generation efficiency of the battery board.

Look at the battery slices: Check the battery slices for broken edges and cracks. Low-level components are mostly spliced with broken cells, which have great potential safety hazards and extremely low power generation efficiency.

Look at the component frame: high-grade components are processed by machine framing, and the frame is neat and sturdy, while low-level components are generally processed by manual framing, which has problems such as frame deformation and instability.

Look at the silica gel: Check whether the silica gel is evenly distributed around the back of the module and whether it penetrates tightly into the gap between the backplane and the frame. Low-level components are generally shoddy and easy to identify.

Of course, for consumers, it is also necessary to confirm whether the module products are from regular brand manufacturers, and carefully check and check the warranty contract, invoice, etc. These details not only determine the quality of solar cells, but also determine the after-sales service and 25-year warranty service .

-

-

How to apply solar energy to agricultural drip irrigation system?+

How to apply solar energy to agricultural drip irrigation system?+Introduction of drip irrigation system:

Drip irrigation is the most advanced and precise irrigation method at present. It uses a low-pressure pipeline system to transport water directly into the field, and then through the dripper, orifice or drip irrigation belt installed on the capillary and other irrigators, the water is dropped drop by drop. It is evenly and slowly dripped into the soil near the root zone of the crop, so that the soil in the area with the most developed crop root system often maintains a suitable humidity, so that the water, fertilizer, gas, heat and microbial activities of the soil are always in good condition, which is conducive to the high yield of crops. Create favorable conditions for stable production. Drip irrigation belts are divided into patch type drip irrigation belts, embedded cylindrical drip irrigation pipes, and labyrinth drip irrigation belts.

The use and laying of drip irrigation tape:

- When laying the drip irrigation tape, care should be taken not to make the drip irrigation tape too tight to avoid installation inconvenience. Too loose will cause waste of drip irrigation belt.

-

When laying the dropper belt, pay attention to clean up the sediment where there is a fracture. Prevent unnecessary troubles such as clogging of the dropper belt in later use.

-

The connection should be fixed well to prevent water leakage. If water leakage is found during use, it should be dealt with in time.

-

When laying the drip irrigation belt under the film, the land must be leveled in advance to remove the gravel and clods to prevent the drip irrigation belt from being damaged. Never allow a large gap between the mulch bump and the drip irrigation tape to prevent the drip irrigation tape from being burned by sunlight. In addition, the dropper tape (tube) can be properly buried to prevent burns.

-

The connection sequence of the dripper belt system is usually: head valve, fertilizer applicator, filter, main pipe, branch pipe, bypass, drip irrigation belt (pipe).

Applicable conditions of drip irrigation belt:

- It is used for planting crops in greenhouses and greenhouses, reducing pests and diseases, saving chemical fertilizers and pesticides, and improving economic benefits.

-

For orchard irrigation, it can effectively increase yield, improve fruit quality, and effectively control the growth of weeds.

-

It is suitable for various field crops such as cotton, Chinese herbal medicine, watermelon, field vegetables, etc., to improve the mechanized planting.

-

The drip irrigation tape can be bent and laid around the ridge, which is easy to operate.

Precautions for use:

- The dripper belt (tube) dripper is easy to be blocked, so a filter must be installed. For poor water quality, in addition to installing a filter with better filtration capacity, sedimentation and chemical treatment can be carried out if necessary.

-

For the dropper tape that has not been used for a long time, you can open the valve to drain a little before use, and then carry out drip irrigation. 3. The use of dropper belt fertilization can only apply liquid fertilizer or easy-to-dissolve fertilizer, not farmyard manure.

-

Due to the high material cost of the dripper belt irrigation method, it is more suitable for economic crops with high added value.

-

Drip irrigation cannot adjust the microclimate of the farmland. During the freezing period, it is not recommended to use the drip tape (pipe) for irrigation.

Drip irrigation is currently the most effective water-saving irrigation method in arid and water-deficient areas, and its water utilization rate can reach 95%. Drip irrigation has higher water-saving and yield-increasing effects than sprinkler irrigation, and can be combined with fertilization to more than double the fertilizer efficiency. It can be used for irrigation of fruit trees, vegetables, cash crops and greenhouses, and can also be used for field crop irrigation in dry and water-deficient places.

-

Do you know the difference between 5 types solar panels?+

Do you know the difference between 5 types solar panels?+When a solar cell is graded, it means that the manufacturer has tested each cell within a particular solar panel to determine how efficient they are. A Solar Panel Grading is based on the types and the degrees of defects that a Panel Includes. These grades have a range from A to D, The difference between 5 types solar panels are solar panel efficiency.

Grade - A : A- Grade solar panels are a type of photovoltaic panels that is considered to be a high-end product.

It usually refers to a panel that is free of flaws (such as missing busbars, missing prints, bends, scratches, etc.) and covered by the manufacturer's regular warranty.

Grade – B : B- Grade solar cells usually has some imperfections or blemishes but has the "same" electrical output as Grade - A.

The difference is that B grade panels are not covered by a manufacturer's standard warranty , they have visual flaws, and their price is a little lower than A Grade panels.

Grade - C : C- Grade solar cells are those with a flaw that affects the power output, so their output is lower than A and B Grade cells, and their price lower.

Grade – D: D- Grade solar cells are generally considered unusable and thrown out by manufacturers.

As a result, each solar panel is given a grading depending on its performance and whether or not it has physical flaws.

-

What's the payment term of Namkoo?+

What's the payment term of Namkoo?+Namkoo accept T/T, L/C, Western union, trade assurance and cash. 30% for deposit and 70% balance before shipment.

-

What certificates does Namkoo have?+

What certificates does Namkoo have?+Namkoo's solar energy products are approved by CE, Rohs, SGS, SONCAP, VDE and other certifications.

-

Can you customize the solar product?+

Can you customize the solar product?+Yes, Namkoo is an experienced solar factory, ODM and OEM customization of solar products are acceptable as according to customer requirement.

-

Is Namkoo a manufacturer or trading company?+

Is Namkoo a manufacturer or trading company?+Namkoo is the solar manufacturer specialized in on grid and off grid solar power system, solar panel, solar water pump system and other solar products over 18 years. Apart from it, we can also provide ODM and OEM services of solar energy system for our customers.