Frequently Asked Questions

Frequently asked questions, we integrate them into self-service Q&A. If you have other questions, you can get in touch with us Or send us an email to: info@southholding.cn

-

The Hidden Dangers of Home Energy Storage–How to Stay Safe+

The Hidden Dangers of Home Energy Storage–How to Stay Safe+The Hidden Dangers of Home Energy Storage–How to Stay Safe

Recent incidents of fires and explosions in the European residential energy storage market have raised serious concerns. From a basement fire in suburban Munich to a garage explosion in northern Italy, these accidents have not only resulted in property damage but have also shaken public trust in clean energy technology.

Explosion of energy storage system in Schleswig-Holstein, Germany

As a seasoned professional in the energy industry, I believe it is crucial to analyze the technical causes behind these incidents and provide consumers with actionable strategies for mitigation.

Understanding the Technical Causes Behind Accidents

1. Thermal Runaway in Lithium Batteries: The Root Cause

Most incidents stem from thermal runaway in lithium-ion batteries. This occurs when internal temperatures rise uncontrollably due to overcharging, short circuits, or external heat, triggering a chain reaction that releases excessive heat and flammable gases, ultimately leading to fires or explosions.

2. System Integration Flaws: Overlooked Risk Factors

BMS (Battery Management System) Failures: Inadequate monitoring or failure to disconnect malfunctioning battery cells in time.

Poor Heat Dissipation Design: Installing systems in confined spaces where heat cannot escape efficiently.

Electrical Connection Issues: Improper installations leading to excessive contact resistance and localized overheating.

3. The Hidden Dangers of Low-Quality Components

To cut costs, some manufacturers use refurbished battery cells or simplify protection circuits, increasing the likelihood of performance degradation and system failure over time.

Consumer Strategies: Prevention and Crisis Management

1. Choosing a Safe and Certified System

- Ensure the product meets international safety standards such as UL 9540A and IEC 62619.

-

Opt for LFP (Lithium Iron Phosphate) batteries, which have superior thermal stability compared to NMC (Nickel Manganese Cobalt) batteries.

-

Request comprehensive testing reports and warranty commitments from suppliers.

2. Ensuring Proper Installation

- Hire certified professionals with VDE or TÜV accreditation.

- Install the system in a well-ventilated area, away from flammable materials.

- Incorporate fire-resistant enclosures and automatic fire suppression systems.

3. Implementing Continuous Monitoring

- Use a mobile app for real-time monitoring of system performance.

- Schedule regular health checks to detect potential risks early.

- Maintain detailed service records for warranty claims and legal protection.

4. Responding to Emergencies

- Immediately disconnect power and evacuate the area before calling emergency services.

- Document the incident with photos and videos for investigation.

- Contact your insurance provider and supplier to initiate claims and remedial actions.

Why Choose Namkoo? Ensuring Safety and Reliability

In a complex and evolving market, selecting a trusted supplier is critical. Namkoo prioritizes safety through:

1. End-to-End Safety Design

- High-consistency battery cells to eliminate thermal runaway risks at the source.

- Triple-redundant BMS system for 24/7 monitoring and protection.

- Customized installation solutions to ensure optimal system integration.

2. International Safety Certifications

Namkoo products comply with UL 9540A, IEC 62619, and CE standards, meeting Europe's most stringent safety regulations.

3. Localized Technical Support

With service centers in different markets, Namkoo offers fast-response installation, maintenance, and after-sales support.

4. Transparent Warranty Commitments

We provide a 5-10 years product warranty and performance guarantee, ensuring peace of mind for our customers

Safety as the Foundation of Energy Transition

Residential energy storage is more than just a technological product—it is a vital part of household energy security. Choosing Namkoo means choosing unwavering quality, a commitment to safety, and a shared responsibility for sustainable development.

Together, let's build a safer, greener energy future.

-

A Global Analysis Tells You Where Is Rooftop Solar Most Effective?+

A Global Analysis Tells You Where Is Rooftop Solar Most Effective?+

A Global Analysis Tells You Where Is Rooftop Solar Most Effective?

As the global push for renewable energy continues, rooftop solar power systems have emerged as a key solution for sustainable electricity generation. However, the effectiveness of rooftop PV systems depends largely on geographic location, solar radiation levels, and regional climate conditions. In this article, we explore the solar radiation zoning and rooftop photovoltaic potential across different regions.

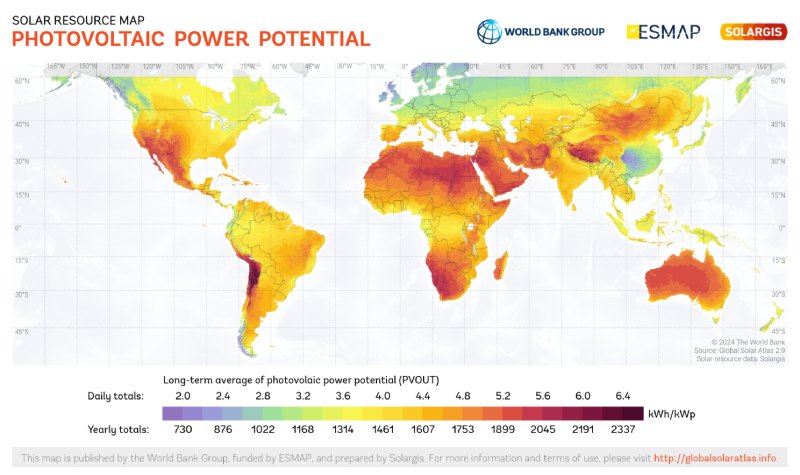

Solar Radiation Zoning and Rooftop Photovoltaic Potential

Equatorial-Tropical Desert Area

Annual Total Radiation: 2000–2500 kWh/㎡ (some areas exceed 2500 kWh/㎡)

- Key Regions: Saudi Arabia, United Arab Emirates, Egypt, central and western desert areas of Australia, Chile, northern desert areas

-

Main Features:

-

High number of sunny days

-

Minimal cloud coverage

-

Stable solar altitude angle

-

Applicability:

-

Ideal for large-scale centralized ground power stations and distributed rooftop solar system

-

Even with limited rooftop space, substantial power generation is possible

-

Competitive Levelized Cost of Electricity (LCOE)

Subtropical-Temperate Sunshine-Abundant Area

-

Annual Total Radiation: 1400–2000 kWh/㎡

-

Key Regions: California, Texas, and southwestern U.S., northwest and north China, most of India

-

Main Features:

-

Seasonal variations in sunlight

-

Above-average global solar radiation (1200–1500 kWh/㎡)

-

Applicability:

-

Suitable for rooftop PV on homes and agricultural facilities

-

Widely used in industrial parks and commercial buildings

Temperate Medium Sunshine Area

-

Annual Total Radiation: 1000–1400 kWh/㎡

-

Key Regions: Inland Germany (1100–1200 kWh/㎡), coastal and inland Japan (1000–1300 kWh/㎡), northern Italy, northern Spain

-

Main Features:

-

Less sunshine compared to deserts and lower latitudes

-

Grid parity achievable with policy support

-

Applicability:

-

Ideal for residential and commercial rooftop installations

-

Policies such as net metering and subsidies enhance economic feasibility

-

Adoption of PV storage systems and bifacial modules can further improve efficiency

High Latitude and Marine Climate Cloudy Areas

-

Annual Total Radiation: Below 1000 kWh/㎡

-

Key Regions: United Kingdom, coastal Northern Europe, northern Canada

-

Main Features:

-

High cloud cover and frequent rainy days

-

Significant seasonal variations in radiation levels

-

Applicability:

-

Requires strong policy and technical support

-

Innovations such as BIPV, high-efficiency modules, and energy storage are crucial

-

Financial incentives improve viability

Rooftop Solar Power System Suitability in Different Regions

Natural Optimal Areas

- Middle East, North Africa, inland deserts of Oceania, southwestern U.S., northwestern China, parts of India

-

High solar radiation and extensive sunny days make rooftop PV highly efficient

-

Short investment payback period

Suboptimal Areas

- Temperate drier or sunny climate zones (Southern Europe, East Asia, Midwest North America)

-

Slightly lower radiation levels but economic benefits remain strong due to high electricity prices and incentives

Areas That Can Be Compensated by Technology and Policy

-

High-latitude, maritime, and rainy regions (e.g., northwestern Europe, the U.K., northern Canada)

-

Rely on policy incentives (net metering, subsidies, tax exemptions) and advanced PV technology (high-efficiency modules, optimized system design)

Namkoo Solar

At Namkoo Solar, we specialize in designing customized solar energy and energy storage systems that best suit your local light conditions and roof structure. Whether you are in a high-radiation desert zone or a cloudy, high-latitude area, Namkoo provides tailored solutions to maximize your energy efficiency and reduce electricity costs.

Our expertise in solar industry ensures that customers receive optimized rooftop solar solutions that align with both natural conditions and regulatory incentives. With Namkoo Solar, you can transition to a cleaner, more sustainable energy future with confidence.

Conclusion

From publicly available solar radiation data, the most suitable regions for rooftop PV are those within equatorial arid and semi-arid area and subtropical-temperate arid area, where annual solar radiation exceeds 2000 kWh/㎡. However, temperate and high-latitude regions can also achieve significant PV deployment with supportive policies, technological advancements, and decreasing solar system costs.

With the right mix of natural conditions, policy support, and innovative PV technologies, rooftop solar system can thrive across the globe, accelerating the transition to a cleaner, more sustainable energy future.

-

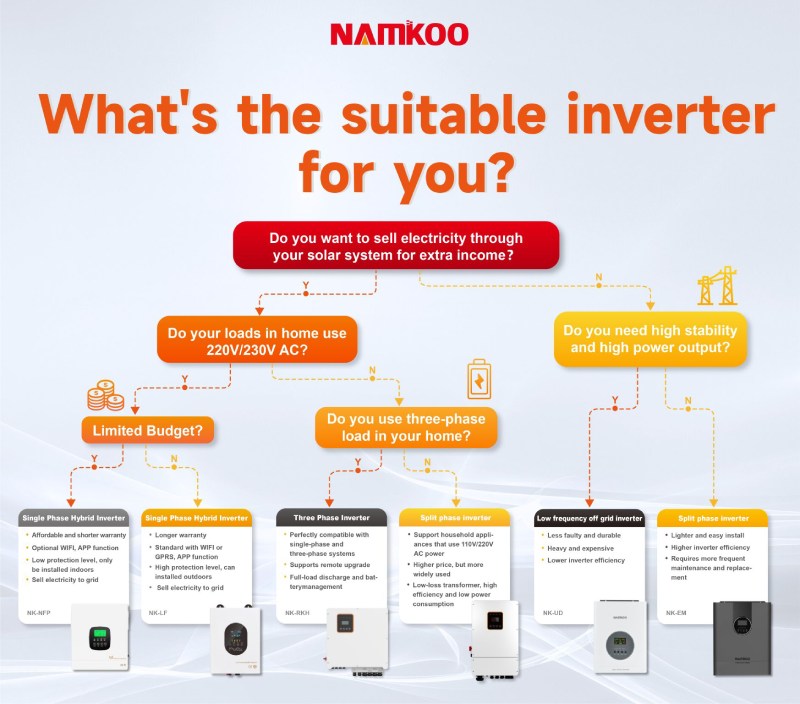

Confused About Choosing the Right Home Inverter?+

Confused About Choosing the Right Home Inverter?+Confused About Choosing the Right Home Inverter?

Let Namkoo Guide You!

Deciding on a home inverter can feel overwhelming with so many options available.

But worry no more—Namkoo's Inverter Selection Guide is here to simplify your decision-making process!

-

Why Choose Namkoo's Stackable Battery?+

Why Choose Namkoo's Stackable Battery?+Why Choose Namkoo's Stackable Battery?

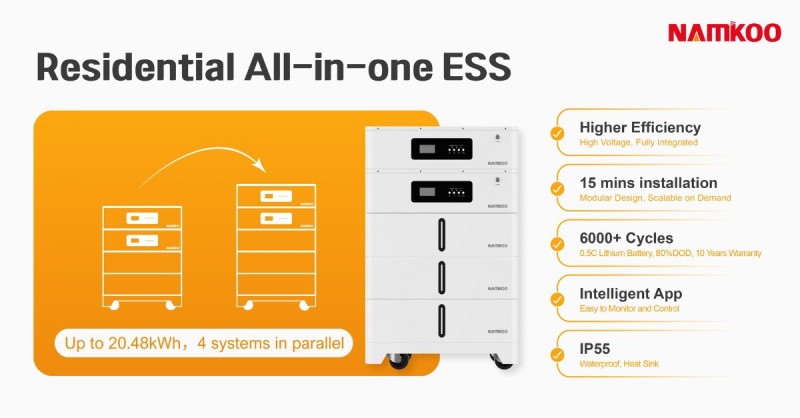

Looking for a reliable and efficient energy storage solution? Namkoo's stackable battery stands out with:

Flexible Capacity: Expand from 10kWh-20.48kWh based on your power needs.

Top-tier Efficiency: Over 98% battery round trip efficiency and 5% CEC-rated inverter efficiency.

Quick Installation: Plug-and-play setup in just 15 minutes!

Durable Performance: >6,000 cycles with a 10-year Namkoo warranty for peace of mind.

Whether you're powering your home or business, Namkoo's stackable battery offers unmatched performance and reliability. Ready to take control of your energy?

WhatsApp: +86 188 2324 9350

Email: info@southholding.cn

-

99% Don't Know How Hybrid Inverters and Diesel Generators Work Together+

99% Don't Know How Hybrid Inverters and Diesel Generators Work Together+99% Don't Know How Hybrid Inverters and Diesel Generators Work Together

1. The Necessity of Hybrid Inverters + Diesel Generators

In regions where the main grid is insufficient or unstable, diesel generators have historically been used as the primary power source. These areas often experience significant fluctuations in power demand, requiring a flexible power supply system:

Emergency Backup Power: Diesel generators can swiftly provide electricity during grid outages or sudden spikes in demand, ensuring a continuous power supply.

Load Balancing: A hybrid solar system can activate the diesel generator during peak load times and switch to solar or energy storage systems when demand decreases, effectively balancing the power sources.

2. Cost-Effectiveness of Lead-Acid Battery

In areas with limited or unstable grid access, lead-acid battery offer distinct advantages in terms of cost and technological maturity:

Lower Costs: Lead-acid battery are generally more affordable than lithium battery, making them an attractive option for energy storage on a budget.

Proven Technology: With years of development, lead-acid battery technology is reliable and widely used, demonstrating stable performance in real-world applications.

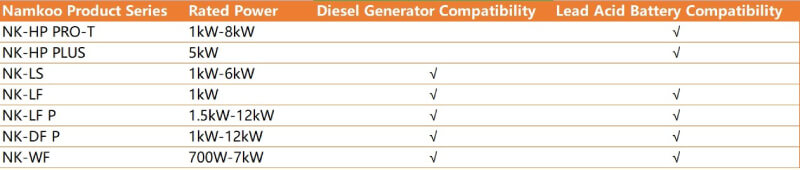

Namkoo Hybrid Inverter Series

3. Working Logic of Hybrid Inverters + Diesel Generators + Lead-Acid Battery

Principle: By coordinating software and hardware, the seamless switching and dynamic scheduling of multiple power sources ensure stable power supply and maximize efficiency.

a. Control Logic

The hybrid inverter combines the strengths of diesel generators and lead-acid battery:

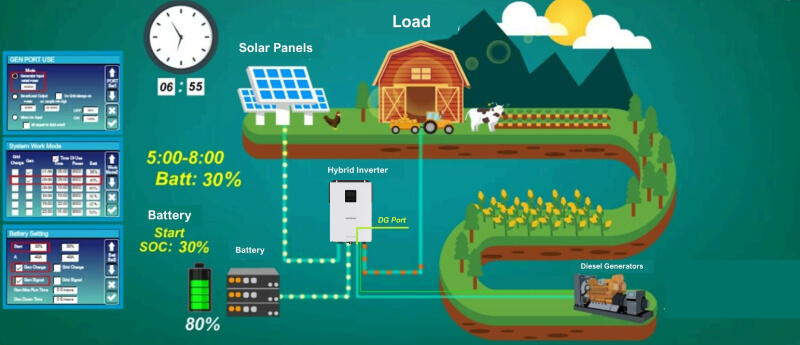

Daytime Power Supply: During the day, the solar PV system prioritizes powering the load while charging the lead-acid battery. This process not only improves renewable energy utilization but also reduces reliance on diesel generators.

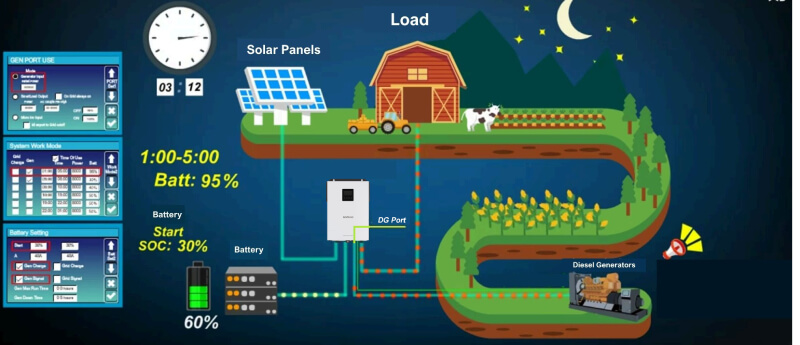

Nighttime or Low-Light Power Supply: At night or in low-light conditions, the stored power in lead-acid battery is used first. If battery power is insufficient to meet the load demand, the diesel generator will automatically start to provide additional electricity.

Load Management: This logic ensures that during grid instability or peak demand periods, the diesel generator can quickly engage to maintain stable power supply, while relying on lead-acid battery during lower load periods to optimize fuel use.

Nighttime or Low-Light Power Supply

In on-grid mode, the priority of solar power generation is determined by settings, whether to prioritize the load or battery supply.

In off-grid mode, daytime solar power first supplies the load, then charges the storage battery. At night, the storage battery discharges to supply the load, and when battery power runs low, the diesel generator takes over. This mechanism ensures a continuous power supply during grid instability or outages.b. Power Scheduling and Fuel Efficiency Optimization

The hybrid inverter system dynamically schedules the diesel generator, solar, and energy storage to reduce fuel consumption by activating the generator during high loads and relying on solar and storage during low loads.

Especially under low load conditions, the diesel generator's fuel efficiency tends to be lower. However, with an integrated control system, the generator can operate closer to its rated power, improving fuel efficiency, typically enhancing fuel utilization by 10% to 15%.

The necessity of hybrid inverters equipped with diesel generator interfaces is knowledge that 99% of people don't know about. Click to learn more.

Daytime Power Supply

4. Market Demand and Application Scenarios

African and Indian Markets

In rural and industrial areas of Africa and India, where grid coverage is inadequate and power supply is unstable, hybrid inverter systems can effectively integrate solar and diesel power to provide reliable electricity.

In rural areas, solar power is used for agricultural irrigation and lighting during the day, while energy storage or diesel generators provide power at night.

Southeast Asia and Middle East Markets

Countries like the Philippines and Indonesia in Southeast Asia, and Saudi Arabia in the Middle East, utilize hybrid inverter systems to address power supply issues in island regions.

South America and Australia

In South America, mining and agricultural areas have high energy demands. Hybrid inverters can balance solar and diesel generation, reducing fuel costs.

These systems are also widely used in remote farms and mining sites in Australia to provide around-the-clock power.5. Namkoo Hybrid Inverter Series

Namkoo now offers hybrid inverter compatible with diesel generators.

Namkoo Hybrid Inverter Series

6. Application Cases

Microgrid Applications

In a remote area, the X microgrid project integrated solar, energy storage, and diesel generators through a hybrid inverter system.

During low sunlight or adverse weather, it automatically switches to diesel power, ensuring that residential or industrial power needs are met. The microgrid reduced diesel usage by 40% through this hybrid system, saving a significant amount of fuel.

Microgrid Solar Power Plant

Commercial and Industrial Applications

At the Y construction site, the hybrid inverter dynamically manages power loads, reducing the frequency of diesel generator usage. By relying on solar during the day and energy storage, the system decreased dependence on diesel at night, resulting in a 20% reduction in overall fuel consumption.

C&I Solar Application

Guangdong Namkoo Power Co.,Ltd

WhatsApp: +86 188 2324 9350

Email: info@southholding.cn

Address: No.133 Jingying International Business Center, Foshan,Guangdong, China

Namkoo community

-

City Saves Money with Solar Sewage Pumping Station+

City Saves Money with Solar Sewage Pumping Station+

City Saves Money with Solar Sewage Pumping Station

Background

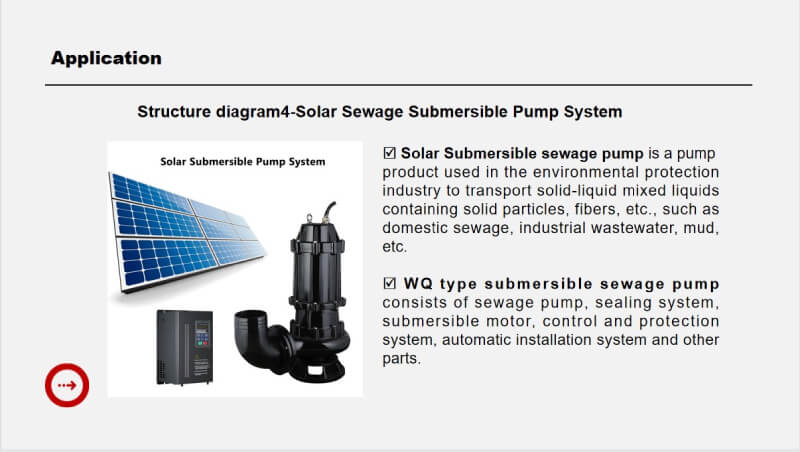

Cities generate large amounts of domestic and industrial wastewater every day, and wastewater treatment is an important task for protecting the environment and human health. However, conventional wastewater treatment facilities usually rely on electricity supply, which not only increases energy costs but also negatively impacts the environment. To solve this problem, sewage solar pump system have emerged.

System Components

The components of this new solar power sewage treatment system consists of solar panels, inverter, three-phase alternating current (AC) control device, intelligent on-grid/off grid device and emergency backup utility grid.

1. Solar System

The station is equipped with highly efficient solar panels for collecting solar energy and converting it into electricity to supply the electricity required for the operation of the facility.

2. Wastewater Treatment Units

The station includes several wastewater treatment units, such as pre-treatment units, biological treatment units and coagulation and sedimentation units. These units work together to remove organic matter, nitrogen, phosphorus and other pollutants from the wastewater.

sewage submersible pump system

3. Control System

The station is equipped with an advanced automatic control system that monitors and regulates the operating status of the facility to ensure efficient and stable operation.

solar-powered wastewater treatment system component

Application

Solar-powered sewage treatment systems can be used in remote areas with limited access to electricity. These systems are well-suited for various situations, including remote mining camps, temporary archaeological sites, farm, temporary labor camps, and small isolated communities that have access to solar energy.

System Advantage

1.Fast running

Solar water treatment system running fast, during the operation of only one sewage pump, a blower, sewage pump running time of less than 1 hour per day, the blower only 1-2 weeks running 1 time, 1 time less than 0.5 hours; and the pump management can be achieved through the increase in automatic control system to run automatically, can be a large number of manpower in the maintenance of a large number of people, and energy consumption is greatly reduced, and therefore run.

2.Energy Transformation

The use of solar green energy is in line with the industrial policy and energy transition of each country. The system is compact and covers a small area, which greatly saves land resources, and the ground can be used for greening.

solar powered sewage pumping station

3.Saving On Operating Costs

The use of solar integration technology, the use of solar energy to provide power, without electricity, almost no operating costs, at the same time, to ensure that the system operates stably for a long period of time, through the effective combination of the grid, peak shaving to fill in the valley, achieve the minimization of operating costs.

4.Off Grid System

In addition to the solar system introduced above, solar system with power storage is also a common choice for sewage projects. This technology is completely separate from the municipal power grid to run alone, the power required for system operation is provided by the solar panels, but need to increase the energy storage system, to meet the normal operation of the system in cloudy and rainy days and other conditions of insufficient light, the energy storage system can meet the function of power supply for 7 days of cloudy and rainy weather.

Project Showcase

Namkoo helped a local village in Cebu, Philippines complete a solar sewage treatment project in 2023. The project consists of 4 sets 11kw solar sewage systems that purify the village's domestic and agricultural sewage and reduce the cost of electricity generated by sewage treatment.

solar wastewater pump system in Cebu, Philippines

Are you still struggling with the high cost of electricity for your city, village, farm, or industrial wastewater treatment system? Try solar powered sewage stations! Immediately save 60%-90% on your electricity bill! Contact Namkoo for your free solar wastewater treatment system design and discounted quote.

-

Namkoo High Voltage BESS for Commercial & Industrial+

Namkoo High Voltage BESS for Commercial & Industrial+Namkoo High Voltage BESS for Commercial & Industrial

In many African countries, unstable power grids lead to frequent outages and voltage fluctuations. C&I energy storage systems act as backup power, ensuring uninterrupted production and equipment safety, avoiding economic losses.

With rapid response capabilities, these systems improve power quality, crucial for precision manufacturing and data centers. They also provide short-term emergency support, enhancing resilience against unexpected power events.

Various factors have led to increased interest in cost-effective high voltage C&I battery energy storage systems in African countries. Through in-depth research and development in Africa, Namkoo has launched an all in one solar power storage cabinet that meets the power needs of users while keeping costs down.

C&I BESS Application

The energy storage system finds diverse applications in industrial parks, commercial buildings, EV charging stations, hospitals, schools, villa areas, and more. Key functions include:

1、Peak shaving and valley filling: Enterprises store electricity during off-peak hours to reduce costs and release it during peak periods, optimizing electricity bills.

2、Backup power: Vital for continuous supply in data centers, hospitals, and manufacturing plants during outages or emergencies.

3、Load balancing: Balances power demand across time periods, cutting peak consumption and electricity bills.

4、Power market participation: Systems engage in power trading, buying low-cost power and selling high-priced power during peak hours for profit.

These applications are just a glimpse; more may emerge over time. Namkoo's SmartBase series tackles these challenges effectively.

Commercial and industrial park with energy storage system

All-in-one Design with 5 Highlights

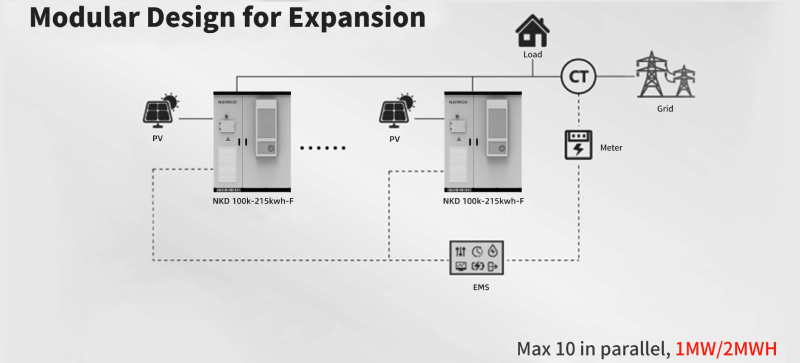

Modular design, flexible expansion, easy operation

The SmartBase series by Namkoo comprises industrial and commercial outdoor storage cabinets featuring hybrid inverters and lithium batteries. With pre-assembled battery packs, installation is swift, taking just one day for setup and debugging on-site. Customers can select from various power segments to suit different backup power needs, ranging from 50kW/100kWh to 500kW/1MW, covering scenarios lasting 2 to 6 hours.

The system allows flexible configuration and parallel connection, accommodating up to 10 units connected to the grid in parallel, achieving a maximum power generation of 2MWh. Off grid mode, three units can be paralleled, max up to 645kWh.

Design for electrical safety

The SmartBase outdoor BESS cabinets feature multiple safety designs to ensure personal and property safety:

1、Aerosol + perfluorohexanone fire-fighting system delivers rapid and precise fire extinguishing.

2、Protection level of IP54 withstands diverse outdoor weather conditions.

3、Full system detection targets overvoltage, overtemperature, short circuit, and cooling system issues.

4、Door-mounted integrated air conditioner maximizes cabinet space, enhances structural integrity, and improves waterproofing

It utilizes A-grade lithium iron phosphate (LiFePO4) batteries with a cycle life of over 6000 cycles at 25°C and 0.5C discharge rate.

Supports 100% unbalanced load

In regions with three-phase unbalanced conditions, industrial and commercial outdoor storage cabinets ensure optimal performance and cost savings. Supporting 100% unbalanced three-phase output and off-grid operation, they cater to single-phase load applications like air conditioning and lighting without additional equipment.

The SmartBase plug-and-play energy storage system has reactive power and harmonic compensation functions, ensuring seamless integration with diverse loads and grids.

It features an anti-backflow function, enabling excess power generation to charge the battery system when the load meets power consumption. This optimally distributes system power consumption, enhances self-use rates, and prevents solar power wastage.

Built-in EMS, multiple certifications

The industrial and commercial outdoor storage cabinet has a built-in EMS and supports multiple operating modes.

With standardized structural design and menu-based function configuration, it allows optional accessories such as photovoltaic charging modules, off-grid switching modules, frequency transformers, and other components for scenarios like microgrids. It integrates into a comprehensive solar energy storage system cabinet.

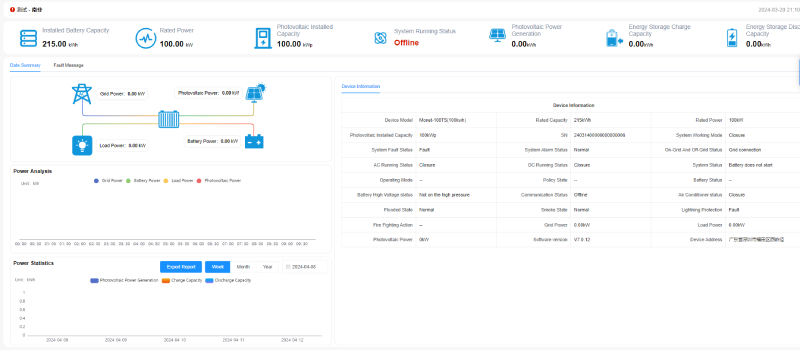

Real-time monitoring, intelligent control

The local control panel can realize various functions such as system operation monitoring, energymanagement strategy formulation, and remote equipment upgrade.

SmartBase Monitoring Cloud Platform

Namkoo's battery energy storage systems, like SmartBase-100, are already powering numerous factories across Africa and Asia, reducing electricity bills and promoting energy autonomy. We're continually exploring new applications and, in line with market expansion and technological advancements, have introduced the SmartBase-001 residential solar power generator to serve homes, schools, and more in these regions.

Namkoo solar power generator SmartBase 001

Drawing on extensive global market experience, Namkoo is committed to enhancing localized service systems and collaborating with local partners to deliver innovative digital energy storage solutions to African customers. Together, we aim to advance sustainable development worldwide.

-

What You Need to Know About Depth of Discharge: Prolong Your System Life+

What You Need to Know About Depth of Discharge: Prolong Your System Life+What You Need to Know About Depth of Discharge: Prolong Your System Life

Batteries are one of the most important parts of energy storage systems. With the reduction in battery cost, improvement in battery energy density, safety and lifetime, ESS is also widely used.

This article will take a look at several important parameters of energy storage batteries and provide an in-depth explanation of depth of discharge, helping you to know how to extend the life of your energy storage system.

Battery Parameters

Battery capacity

Battery capacity is one of the important performance indicators to measure the performance of the battery, the capacity of the battery has a rated capacity and the actual capacity of the battery.

C-rate

C is used to indicate the battery charge/discharge capacity rate.1C,2C,0.5C is the battery discharge rate. When the capacity used is discharged in 1 hour, it is called a 1C discharge; when it is discharged in 2 hours, it is called a 1/2 = 0.5C discharge.

The calculation formula is:

Charge rate=charge current/rated capacity

Discharge rate=discharge current/rated capacity

The higher the discharge current. The shorter the discharge time.

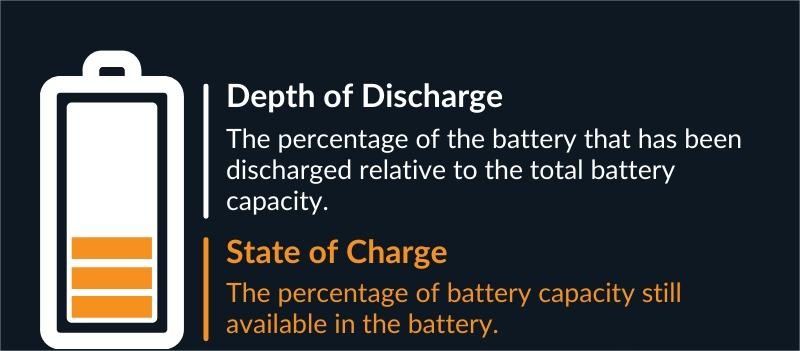

SOC(State of charge)

The battery's state of charge refers to the disparity between a fully charged battery and the battery in use, indicating the amount of remaining electricity in the cell. This is calculated by dividing the remaining charge in the battery by the maximum charge it can deliver.

SOH(State of Health)

SoH of a battery describes the difference between a battery being studied and a fresh battery and considers cell aging.

It is defined as the ratio of the maximum battery charge to its rated capacity.

Generally when the capacity (SOH) of a battery drops to about 70% to 80%, it can be considered to have reached EOL (end of life). SOH is an indicator that describes the current health status of the battery, while EOL indicates that the battery has reached the end of life and needs to be replaced. By monitoring the SOH, it is possible to predict when a battery will reach EOL and to maintain and manage it accordingly.

DOD (Depth of Discharge)

DOD is a measure of the percentage between the amount of battery discharge and the rated capacity of the battery. For the same battery, the depth of DOD set is inversely proportional to the battery cycle life; the deeper the depth of discharge, the shorter the battery cycle life. Therefore, it is important to balance the required runtime of the battery with the need to extend the cycle life of the battery.

For example, a battery with 5 kWh of power and 4 kWh of used power would be discharged to a depth of 80%.

Depth of discharge and state of health

Why is DOD important?

As more and more companies offer energy storage solutions, it has become common for consumers to find the right battery. DOD (Depth of Discharge) is one of the most critical factors you must consider when purchasing a battery energy storage system.

Effect of DOD

The deeper the discharge, the more likely the battery life will be shortened. Fully discharging a battery is generally not recommended as it can significantly shorten the life of the battery.

Many battery manufacturers now give recommended discharge depths in their specifications, which indicate the extent to which the battery should be discharged as far as possible without damaging the battery structure. For example, if the maximum manufacturer's recommended depth of discharge for a 10 kWh battery is 80%, no more than 8 kWh of battery power should be used without recharging.

How does deep discharge affect battery life?

A high depth discharge is when a battery begins to release more energy in a specific amount of time. This can sometimes happen when a battery is deformed in mass. In most cases, deep discharging will significantly shorten the life of the battery, so you will have to pay more for energy storage.

In terms of the effect of deep discharge on battery life, frequent charging and discharging will result in a shorter life. Therefore, it is recommended that you avoid discharging the battery beyond its deep discharge value.

How do you keep your battery healthy?

Now you know how deeply discharged batteries are, it is important to protect them from life loss.

Therefore, in this part, we share some tips that will help enhance the health or life of your batteries:

1、Avoid temperature extremes when storing or using your batteries, and don't expose your batteries to temperatures that are too low or too high, as these temperature extremes can accelerate degradation of the battery components.

2、Minimize the amount of time the battery is left at 0% or 100% state of charge, as these extremes can stress the battery. Therefore, it is recommended that you charge the battery to 80% rather than 100%.

3、Try to keep the battery in a controlled environment at room temperature, between 20 °C and 25 °C.

4、Do not store the battery in an area with high humidity.

In commercial and industrial application, we typically protect batteries from the environment and temperature by using cabinets. Namkoo's new all in one C&I battery energy storage system are designed to protect the batteries and prolong the whole system lifetime.

Namkoo commercial solar storage energy system

This series of products has built-in PCS, EMS on-grid switching unit, power distribution unit, temperature control system, BMS system, fireprotection system, anti-surge device, etc. Cabinet design, easy to transport. IP55/1P65 protection level, can withstand various climatic environments.

Conclusions

An energy storage system is made up of multiple components, and the charging/discharging conditions of the battery can directly affect the system's life. In addition, make sure you follow the lithium-ion battery manufacturer's recommended usage instructions to protect the battery!

-

Do you know there are A B C grade for solar cell?+

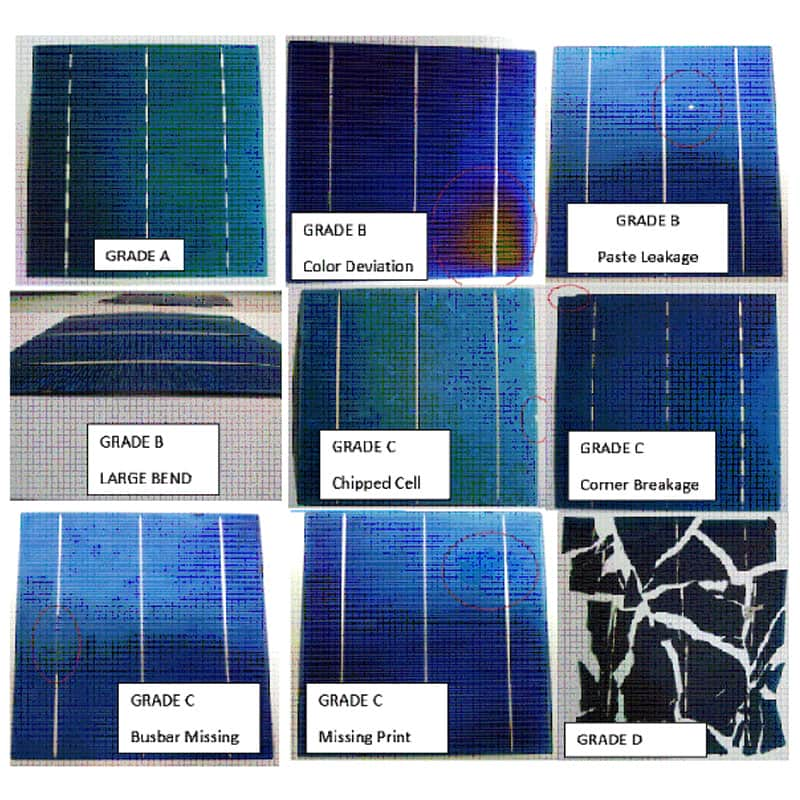

Do you know there are A B C grade for solar cell?+The grades of solar cell modules are generally divided into A grade, B grade, and C grade, and A grade modules can be divided into A+ and A- grades. Different grades of solar cell modules have a certain cost gap. We will briefly introduce the three grades of A, B and C:

-

grade modules: A-grade is the highest quality grade of cells, and the modules can be used perfectly.

-

level modules: B-level cells are slightly lower than A-level cells, and the modules can be downgraded.

- level modules: C-level cells are those with serious bad appearance and missing corners. These cells can be cut into small modules and supplied to customers with special needs.

For manufacturers, the following three points can be used to detect whether the solar cells meet the usage standards:

Before the case is encapsulated

Visual inspection of battery samples:

The color of the upper surface of the battery should be uniform, no mechanical damage, and no oxidation spots on the solder joints. The upper electrode of the battery and the bottom electrode of the battery should not fall off. The anti-reflection coating should not peel or discolor. Use vernier calipers and micrometers to measure the dimensions and thickness of battery samples, which should conform to product production standards.

After the shell is encapsulated

Physical size check:

Check the physical characteristics and size requirements of the standard battery, such as the distance between the upper surface of the standard battery and the encapsulation glass of the casing, and the size of the encapsulation casing, which conform to the actual product standards.Appearance defect inspection:

After the standard battery is packaged, the appearance defect inspection is carried out, focusing on checking whether the material has internal reflection, and the defects that may be caused during the packaging process, such as air bubbles, delamination, unclear marking, etc. In general, bubbles and delamination defects are the most critical.

For consumers, the quality of solar cells can be judged from the following four points:

Look at the surface of the module: Check whether the surface of the module is smooth and meticulous. Low-grade products are relatively rough, and the residual silica gel on the surface will reduce the power generation efficiency of the battery board.

Look at the battery slices: Check the battery slices for broken edges and cracks. Low-level components are mostly spliced with broken cells, which have great potential safety hazards and extremely low power generation efficiency.

Look at the component frame: high-grade components are processed by machine framing, and the frame is neat and sturdy, while low-level components are generally processed by manual framing, which has problems such as frame deformation and instability.

Look at the silica gel: Check whether the silica gel is evenly distributed around the back of the module and whether it penetrates tightly into the gap between the backplane and the frame. Low-level components are generally shoddy and easy to identify.

Of course, for consumers, it is also necessary to confirm whether the module products are from regular brand manufacturers, and carefully check and check the warranty contract, invoice, etc. These details not only determine the quality of solar cells, but also determine the after-sales service and 25-year warranty service .

-

-

How to apply solar energy to agricultural drip irrigation system?+

How to apply solar energy to agricultural drip irrigation system?+Introduction of drip irrigation system:

Drip irrigation is the most advanced and precise irrigation method at present. It uses a low-pressure pipeline system to transport water directly into the field, and then through the dripper, orifice or drip irrigation belt installed on the capillary and other irrigators, the water is dropped drop by drop. It is evenly and slowly dripped into the soil near the root zone of the crop, so that the soil in the area with the most developed crop root system often maintains a suitable humidity, so that the water, fertilizer, gas, heat and microbial activities of the soil are always in good condition, which is conducive to the high yield of crops. Create favorable conditions for stable production. Drip irrigation belts are divided into patch type drip irrigation belts, embedded cylindrical drip irrigation pipes, and labyrinth drip irrigation belts.

The use and laying of drip irrigation tape:

- When laying the drip irrigation tape, care should be taken not to make the drip irrigation tape too tight to avoid installation inconvenience. Too loose will cause waste of drip irrigation belt.

-

When laying the dropper belt, pay attention to clean up the sediment where there is a fracture. Prevent unnecessary troubles such as clogging of the dropper belt in later use.

-

The connection should be fixed well to prevent water leakage. If water leakage is found during use, it should be dealt with in time.

-

When laying the drip irrigation belt under the film, the land must be leveled in advance to remove the gravel and clods to prevent the drip irrigation belt from being damaged. Never allow a large gap between the mulch bump and the drip irrigation tape to prevent the drip irrigation tape from being burned by sunlight. In addition, the dropper tape (tube) can be properly buried to prevent burns.

-

The connection sequence of the dripper belt system is usually: head valve, fertilizer applicator, filter, main pipe, branch pipe, bypass, drip irrigation belt (pipe).

Applicable conditions of drip irrigation belt:

- It is used for planting crops in greenhouses and greenhouses, reducing pests and diseases, saving chemical fertilizers and pesticides, and improving economic benefits.

-

For orchard irrigation, it can effectively increase yield, improve fruit quality, and effectively control the growth of weeds.

-

It is suitable for various field crops such as cotton, Chinese herbal medicine, watermelon, field vegetables, etc., to improve the mechanized planting.

-

The drip irrigation tape can be bent and laid around the ridge, which is easy to operate.

Precautions for use:

- The dripper belt (tube) dripper is easy to be blocked, so a filter must be installed. For poor water quality, in addition to installing a filter with better filtration capacity, sedimentation and chemical treatment can be carried out if necessary.

-

For the dropper tape that has not been used for a long time, you can open the valve to drain a little before use, and then carry out drip irrigation. 3. The use of dropper belt fertilization can only apply liquid fertilizer or easy-to-dissolve fertilizer, not farmyard manure.

-

Due to the high material cost of the dripper belt irrigation method, it is more suitable for economic crops with high added value.

-

Drip irrigation cannot adjust the microclimate of the farmland. During the freezing period, it is not recommended to use the drip tape (pipe) for irrigation.

Drip irrigation is currently the most effective water-saving irrigation method in arid and water-deficient areas, and its water utilization rate can reach 95%. Drip irrigation has higher water-saving and yield-increasing effects than sprinkler irrigation, and can be combined with fertilization to more than double the fertilizer efficiency. It can be used for irrigation of fruit trees, vegetables, cash crops and greenhouses, and can also be used for field crop irrigation in dry and water-deficient places.

-

Do you know the difference between 5 types solar panels?+

Do you know the difference between 5 types solar panels?+When a solar cell is graded, it means that the manufacturer has tested each cell within a particular solar panel to determine how efficient they are. A Solar Panel Grading is based on the types and the degrees of defects that a Panel Includes. These grades have a range from A to D, The difference between 5 types solar panels are solar panel efficiency.

Grade - A : A- Grade solar panels are a type of photovoltaic panels that is considered to be a high-end product.

It usually refers to a panel that is free of flaws (such as missing busbars, missing prints, bends, scratches, etc.) and covered by the manufacturer's regular warranty.

Grade – B : B- Grade solar cells usually has some imperfections or blemishes but has the "same" electrical output as Grade - A.

The difference is that B grade panels are not covered by a manufacturer's standard warranty , they have visual flaws, and their price is a little lower than A Grade panels.

Grade - C : C- Grade solar cells are those with a flaw that affects the power output, so their output is lower than A and B Grade cells, and their price lower.

Grade – D: D- Grade solar cells are generally considered unusable and thrown out by manufacturers.

As a result, each solar panel is given a grading depending on its performance and whether or not it has physical flaws.

-

What's the payment term of Namkoo?+

What's the payment term of Namkoo?+Namkoo accept T/T, L/C, Western union, trade assurance and cash. 30% for deposit and 70% balance before shipment.